Back

Learn more about our

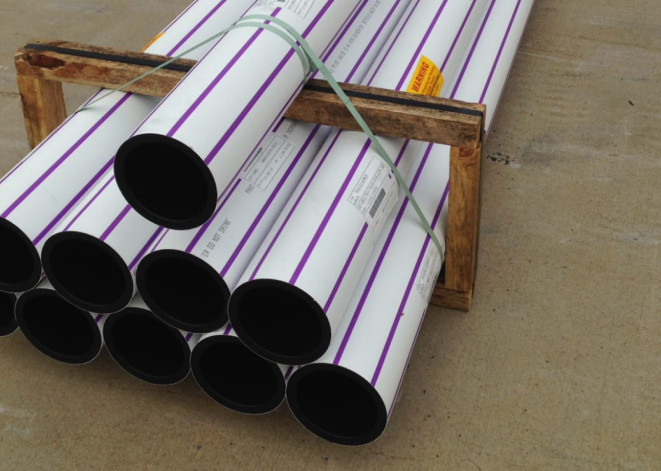

DN63 SDR13.6 Polyethylene Pipe White Telco Co-Extruded White X 140M

TTCX1363140

Overview

Product Properties

Size

63MM

Rating

SDR13.6

Length

140M

Primary Material

POLYETHYLENE

UOM

COIL

Joint Type

Electrofusion, compression, butt-weld, mechanical

Colour

White coating

Coating Specification

White

Allowable Operating Temperature - Degrees

Refer Page 3_Table 2 | https://www.iplex.com.au/assets/Uploads/dc73cc0a04/POLIplex-PE-Pipes-Fittings-Technical-Guide.pdf

Allowable Operating Pressure - 20 Degrees Celsius

1250 kPa @20℃

Minimum Radius of Curvature

21 (x DN) Ref: POP202 Nov2016

Unprotected UV Exposed

2 years in accordance with AS/NZS 2033:2008

Maximum Support Spacing of Pipe Graded

0.50m (If longer spans required, refer Iplex Sales Engineer)

Maximum Support Spacing of Pipe Vertical

1.05m

Industry Specific Names

poly pipe, PE, polythene, polyethylene pipe, HDPE

Mechanical Properties

Ultimate Tensile Strength

N/A

Yield Strain

10%

Yield Stress

25 MPa

Compressive Strength

32MPa

Tensile Modulus

900 MPa

Hardness Shore D

63

Poissons Ratio

0.4

Design Stress

8 MPa

Ring Bending Modulus - 3mins

950MPa

Ring Bending Modulus - 50yrs

260MPa

Thermal Properties

Coefficient of Thermal Expansion

1.8 x 10-4/℃

Thermal Conductivity

0.38W/m.K

Specific Heat

1.9 kJ/kg.K ℃

Vicat Softening Temperature

116℃

Flammability

Supports combustion, will burn when sufficient heat and oxygen are provided

Fire Index - Ignitability

13

Fire Index - Smoke Developed

3

Fire Index - Spread of Flame

7

Fire Index - Heat Evolved

6

Dimensions

Size

63MM

Inner Diameter

53.3mm

Weight

123kg

Wall Thickness

5mm

Standards & Accreditations

Product Standard

Manufactured to AS/NZS 4130 from resin complounds complying with AS/NZS 4131

POP Documents

PIPA Guidelines & Notes (iplex.com.au)

Learn more about our

Electrical and Telecommunication products