Iplex’s manufacturing capabilities enables our team to work with customers to provide customised solutions.

Project Overview

The Iplex team work with customers to assist in providing solutions for each project. The combination of our experienced sales and manufacturing teams allows us to produce bespoke products.

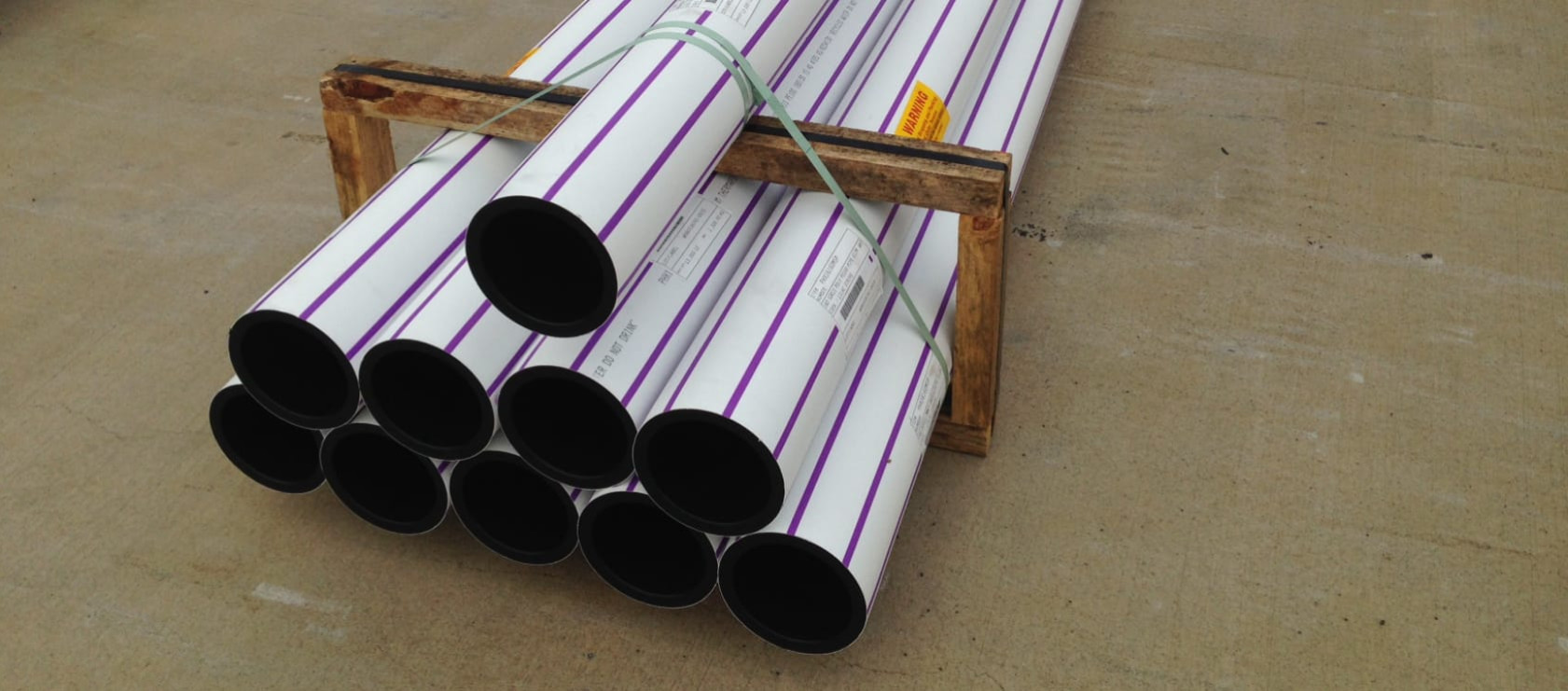

With the new airport runway in Brisbane currently in construction, our Irrigation team worked with a client to supply pipe to establish turf for the runway. The PN10 PE100 THERMAPIPE® white coex pipe with purple stripe will be installed above ground to voids under the ground when planes land. Using a highly reflective white material on the external skin, THERMAPIPE® reduces the absorption of heat. The white material is extruded concurrently with the black pipe wall, forming an integral part of the pipe.

Formulation of the white compound with stabilizers increases the longevity of UV resistance in the outer layer.

Iplex supplied sizes ranging from DN75 through to DN400 in coils and straight 12m lengths. The pipe will be in use for approximately 18 months to establish the turf after which the THERMAPIPE® will be removed and decommissioned.