Iplex’s range of non-pressure PVC pipes, fittings and associated products can be divided into the categories of: DWV, Telecommunications & Electrical Conduit and Stormwater. Iplex also offers a range of solvent cements, primers and lubricants to complement the pipes and fitting range. If you already know what you need, feel free to enquire today. If you need more assistance, don't hesitate to contact us.

EnquireProduct sub-systems

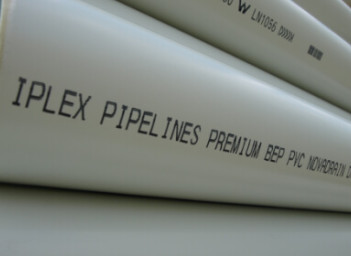

Iplex Non Pressure PVC Pipes Explained

Proudly standing as one of Australia’s leading residential, industrial and commercial plastic pipe manufacturers, Iplex manufactures high-quality PVC non-pressure products to Australian standards. From electrical conduit to stormwater pipes, Iplex's non-pressure PVC pipes are engineered and produced with high-quality materials and robust quality control. Browse the range today.

Need help?

To speak with an Iplex sales & service team member